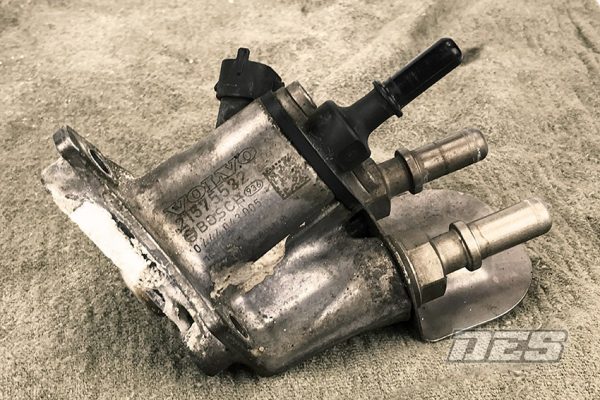

Recently one of our diesel repair techs came across some bizarre looking formations on a customer’s aftertreatment emissions system – specifically around the DEF Doser.

This mess around the DEF Doser indicates a major problem with the SCR section of the aftertreatment system and caused the truck to “de-rate” itself.

What does “de-rate” mean? You probably already know, but for those that don’t…

In a de-rate condition, the ECM (Engine Control Module) limits the horsepower and/or speed of the truck, sometimes to as slow as 5 mph. The ECM is hard-coded to do this when it detects certain problems with the engine such as low coolant, low oil pressure, etc and especially any fault codes related to the emissions system. This is to protect the engine as well as prevent unwanted emissions.

It’s recommended that the driver get the vehicle serviced immediately. Driving with a de-rate may cause permanent damage to your engine or emission system. Be cautious when driving with an active de-rate and get into a service shop as soon as you can to figure out what the issue is.

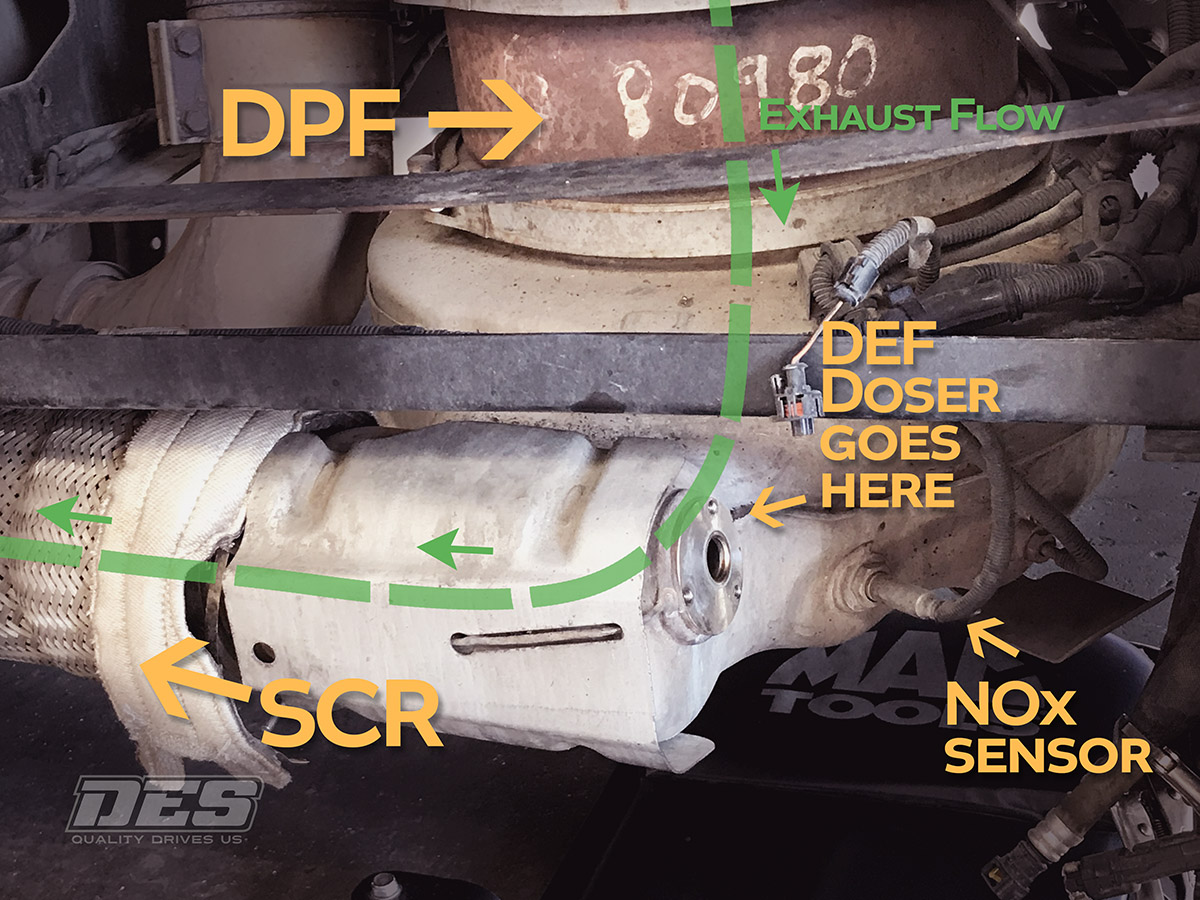

In this case, it was obvious the DEF Doser was not functioning as it should. That white powder is DEF that was found its way out of what is designed to be a closed system.

With DEF (diesel exhaust fluid) leaking out in places it shouldn’t, the DEF was not being injected properly. DEF fluid converts to ammonia which reacts with the NOx gases turning them into harmless nitrogen and water. That reaction is constantly monitored by the inlet and outlet NOx Sensors.

What’s the point of all this? It illustrates the importance of regular, scheduled maintenance for your fleet/truck’s emissions aftertreatment system. All components should be inspected and any codes investigated. Even a failure of a small, relatively inexpensive part (in this case a DEF Doser) can lead to costly and frustrating downtime. A great time to do this is when a DPF is being cleaned.

At DES we not only clean your DPFs, we have trained diesel techs who can inspect and diagnose your truck’s aftertreatment system for issues.

We recommend whoever you have service your diesel emissions components that they regularly and proactively take into account the complete aftertreatment system. In the long run, it’s well worth it.

We hope you found this DES Tech Tip helpful. At DES believe in putting out educational and informative content to not only our customers, but for the general industry to grow and benefit from.

To share this article use one of the social media icons above.